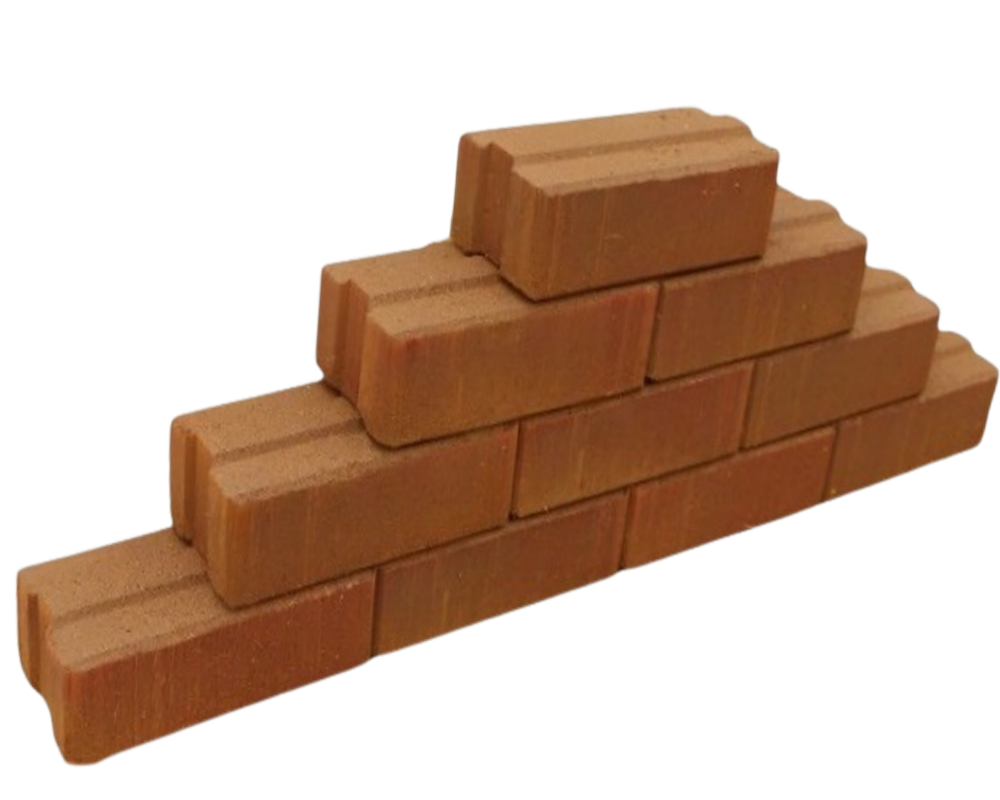

Automatic interlocking block making machines are becoming

increasingly popular in the construction industry due to

their speed and efficiency in producing interlocking

blocks. They are particularly useful in all over countries

where there is a high demand for affordable housing and

construction materials. With the ability to produce

interlocking blocks quickly and at a low cost, these

machines are helping to improve access to safe and

affordable housing for people around the world.

Automatic interlocking block making machines are equipped

with a programmable logic controller (PLC) that allows the

operator to control and monitor the machine's operations,

including block production, mixing, and conveyor

movements.

- No need of mortar & plastering

- Saving on river sand

- Speedy construction & Time saving

- Cost Savings up to 40%

- More Eco-Friendly

- Fewer Labour Cost

- Earthquake Resistant

- Strong Technology

- Less Water

- Cooler Interior