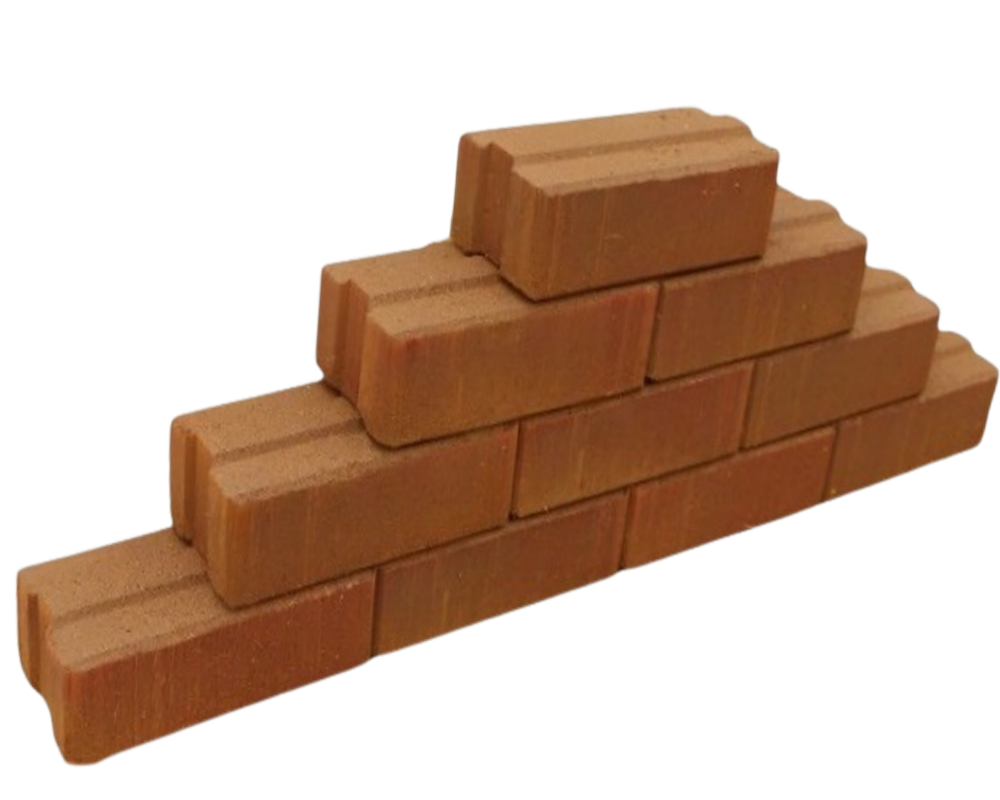

An Automatic Interlocking Block Making Machine streamlines block production with minimal manual

effort, ensuring precision, durability, and efficiency. These machines use advanced automation to

produce

high-quality interlocking blocks, reducing labor costs and material waste. Perfect for large-scale

construction projects, they enhance productivity while maintaining eco-friendly practices.

Upgrade to an Automatic Interlocking Block Making Machine for faster, cost-effective, and

sustainable

building solutions.

✅ High Output | ✅ Eco-Friendly | ✅ Cost-Effective